|

||

|

|

|

Surf wax manufacturers typically provide a recommended temperature range for what water temperatures the wax performs best at. This is somewhat relative as personal preference may allow one to prefer one wax over another under specific conditions. In general waxes tend to become softer as the temperature of the wax increases and likewise waxes get harder as the wax temperature becomes colder. The texture and "stickiness" of some waxes depends on the hardness and hence the temperature. Hard wax has less stickiness” to it and one tends to want a certain feel or grip to the wax. This texture of traction, or stiction, is adjusted by changing the wax hardness by varying the use of different grades of wax. In general as water temperatures rise, the wax needs to stay harder at the higher temperatures and as the water gets cooler the wax needs get softer. The basic trend is:

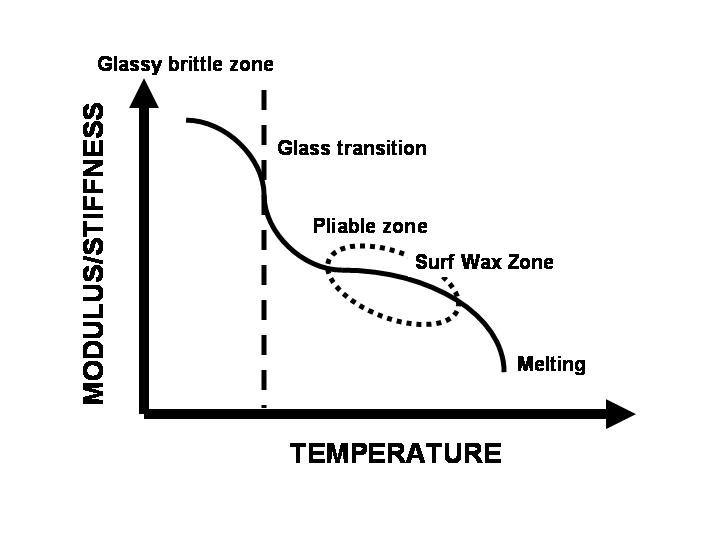

If you buy a few different brands of wax for all the same recommended water temperature, you can quickly see that there is quite a bit of variety with wax hardness for the same recommended water temperature range. This give users some choices as they can decide what wax brand and temperature range works best for them at whatever their skill level, board style, and surfing style. Wax is an unusual material in that it typically has a range of melting point, and this melting point range is relatively close to ambient or the outside temperatures. Waxes are hydrocarbon materials and have some unusual behavior in their physical properties as they get close to their melting point. If you have ever melted grease, wax, or plastics you can see this. The material does not always “melt” like an ice cube but can transition through various grades of being a semi-solid like material. If you slowly heat up wax, wax can become soft as it approaches the melting point and can become more flexible and pliable. Whereas an ice cube does not “become” soft when it is very close to it melting point, such as in a glass of cold water. This variation in the material properties of wax are part of what makes surf wax useful. One generally wants some wax that has some degrees of softness to provide the needed traction. Other sticky wax applications, like grip wax on cross country skis, has similar behavior. The most common method for characterizing wax hardness is with a needle or cone penetration test. This is a controlled test whereby a needle with a certain size is pressed into the surface of the material with a controlled force for a fixed period of time. The depth of penetration of the needle or cone into the material is measured and this penetration depth is an indication of the hardness of the material. One can then compare the hardness of materials with a quantitative measurement of this penetration depth. There are numerous penetration and indentation methods to characterize the hardness of materials, from very hard metals to very soft semi-solid foods, like yogurt. In the case of waxes like surf wax, the most likely best method is ASTM D1321, Standard Test Method for Needle Penetration of Petroleum Waxes. ASTM stands for the American Society of Testing and Materials. Surf wax will behave somewhat like a thermosetting polymer such as polyethylene, which is quite similar to petroleum products like gasoline, kerosene and paraffin like waxes. The relative stiffness or modulus of the wax will decrease as the temperature increases. This typically behaves as shown in the figure below. At very low temperatures, the material is very stiff and brittle and if stressed enough will fracture like "glass". As the temperature increase, this brittle behavior transitions to a more rubbery like behavior and the material becomes more pliable. Surf wax becomes more useful when the wax is pliable and less brittle. As the temperature increases further, the wax will become softer and softer and more pliable and rubber like until it starts to melt.

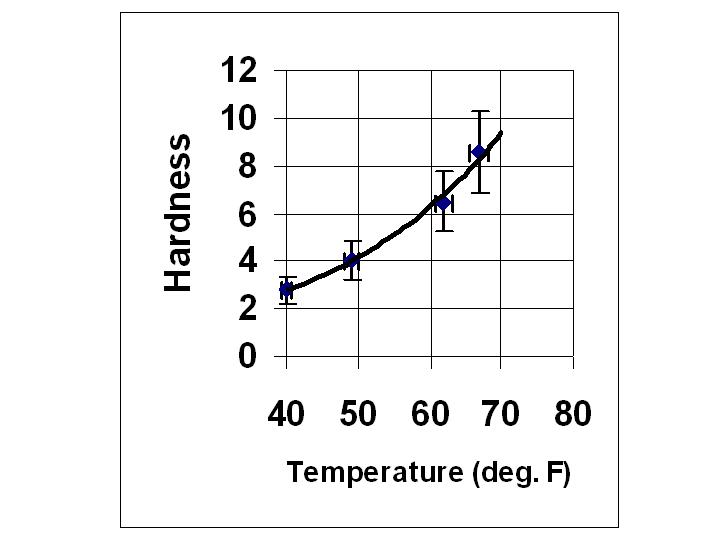

Surf Wax Hardness Testing and Test DataWe built a simple wax hardness test apparatus which can measure wax hardness in a similar manner to a needle penetrometer. This equipment measures the rate that a penetrating needle moves into a wax sample. This creates a semi-quantitative wax hardness scale. For a soft wax, the needle penetrates faster and the number is higher. For a harder wax, the needle penetrates slower and the wax hardness value is lower.

Wax hardness also changes with temperature. As the temperature increases, the wax hardness decreases (and the wax hardness value increases). This data can be used to compare different waxes to each other. If you have a preferred wax and use it at specific temperature, you can use this data to check the approximate wax hardness for that temperature. If you like that hardness, you can use the table to find other waxes that have comparable hardness at that temperature or other temperatures. It is likely that you will prefer a specific hardness and you will adjust your wax to achieve the desired hardness under different water temperatures. We are still testing waxes and will update this data table as more data becomes available. Note that some of these values will likely change as we acquire more data.

An example of some of the test data used to produce the values in this table is shown in the figure below.

Here is some more interesting comments from the US Department of Energy, Argonne National Labs on why wax is soft. From: http://www.newton.dep.anl.gov/askasci/chem03/chem03762.htm Wax, Covalent Bonds, and MeltingQuestion from Jennifer a Canadian student grade 9-12. Question - Candle wax is composed partly of C18H38 (They are subscripts^-^) The covalent bonds between the atoms in these molecules are extremely strong. Yet wax is soft and has a low melting point. Why? You are correct, the bonds between the ATOMS in a single MOLECULE of candle wax -- the C-C bonds and the C-H bonds -- are very strong (both between 330 and 360 kJ/mol) depending upon the particular molecule. In contrast, there is no chemical bond between one MOLECULE of candle wax and another MOLECULE of candle wax. There is a weak attractive force between one MOLECULE and another MOLECULE (about 1 kJ/mol). This is due to the movement in the electrons in one molecule movement of electrons in neighboring molecules (the name for this attraction is "van der Waals forces"). Although the molecules are tangled, the attraction between them is weak. A fair analogy is a bowl of hot wet spaghetti. Each strand is strong, but the strands can slide by one another rather easily. This is why waxes are soft and have low melting temperatures. The wax molecules can slide by one another. Some waxes are harder/softer than others depending upon the length of the carbon chain (longer is harder) and branches in the carbon chain (the more branching is harder up to a point). Vince Calder Jennifer, Even though the covalent bonds are strong between the atoms of any SINGLE molecule of wax, it is the bonding interactions between many molecules that result in the bulk properties of the compound. C18H38 is a hydrocarbon and most lower molecular weight hydrocarbons are in fact liquids. In fact C18 is right on the verge of being a liquid. If you take away a couple carbons to get into the C12-C15 range, you have kerosene fuel and in the average molecular formula for diesel fuel is C12H26. You can see that the addition of just a few more carbons can change the bulk properties of the compound from a liquid to a solid, in this case a waxy solid. The reason for the waxy feel is because the molecule is composed of only hydrogen and carbon. Hydrocarbons are very greasy and repel water, hence why you wax your car! Matt Voss Jennifer, While you are correct that the C-C bonds are quite strong, the cohesiveness of a solid is due more to how well the molecules bind to each other. The cohesion strength of molecules is due to many factors: the strength of the intermolecular forces, how well the molecules fit into each other, the mobility of the components within the molecule, etc. It so happens that wax has a very weak intermolecular attractive force (London Forces) and so it does not hold on to other molecules very well. Also, because it is a relatively short and flexible chain (think of short bits of thread) it does not fit well with other molecules like itself (as opposed to really long chains that can entangle other chains, or rigid structures like cubes or squares that can stack on top of each other). As such, wax tend to be soft and amorphous. Greg (Roberto Gregorius) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|